-- No items so far --

Water clarity isn't optional—it's everything. The S-Series delivers crystal-clear water held at your exact temperature, monitored by micro-sensors that track pH, temperature, and sanitizer levels like an Olympic facility. The data flows to your phone in a single, elegant dashboard that reads like a financial ledger. No surprises, only confirmation that everything is precisely as it should be.

While others rely on concrete that cracks and corrodes, the S-Series is built around aerospace-grade tubular steel—the same engineering principles that keep aircraft aloft. Each wall uses 80-ksi high-strength tubes, precision-welded to create a monocoque frame so rigid the entire vessel can be lifted by a single corner with minimal flex.

Testing confirms wall deflection under full water pressure at less than 1/16 inch across 20 feet—six times stiffer than 8-inch concrete and entirely immune to the micro-fractures that plague traditional pools.

Think of a modern jet fuselage: interior and exterior skins with an insulated cavity and rigid internal truss. S-Series panels follow the same logic. Dual hot-dip-galvanized steel skins sandwich a closed-cell polyurethane core rated at R-10, preserving heat in winter and expelling excess warmth in summer.

The result? A thermally stable environment that protects chemistry and deters algae before it can form.

Stronger Than 6" Gunite Pools

Faster Installation Than Traditional Pools

Cheaper to Maintain Than Gunite Pools

Water clarity hinges on two simple tasks: neutralize pathogens instantly and maintain a gentle oxidant residual. The S-Series accomplishes both with a commercial-grade UV-C reactor paired to a micro-dosing sodium-hypochlorite pump.

The UV chamber deactivates 99% of viruses and bacteria in one pass, while downstream dosing keeps free chlorine near 0.5 ppm—the same level as municipal drinking water. Vapor, odor, and fabric bleaching are effectively erased.

Advanced probes measure pH, ORP, and temperature every hour. A processor running predictive algorithms interprets the data and recommends adjustments before deviations become noticeable. A 24-volt robotic cleaner maps the pool with advanced navigation, scrubs on an optimized path, and operates automatically.

The technology works in complete silence.

Imagine the fuselage of a modern jet. Interior and exterior skins, insulated cavity, rigid internal truss. Ecopool panels follow the same logic. A matrix of precision-crafted high strength steel tubes, hand-welded to form a shape that locks tension, compression, and shear into predictable vectors.

Testing confirms wall deflection under full hydrostatic pressure at less than 1/16 inch across 20 feet—six times stiffer than 8 inch concrete and entirely immune to micro-fracture and the infamous concrete cancer. Over this skeleton, dual hot-dip-galvanized steel skins sandwich a closed-cell polyurethane core rated at R-10, preserving heat in winter and expelling excess warmth in summer. Joints between modular assemblies are made tube-to-tube, creating a monocoque that can be assembled on-site.

S-Series modules are born in a precision manufacturing facility that borrows process controls from the aerospace sector. CNC plasma machines cut every tube while hot air welders lay seams with consistency rarely attempted in outdoor construction.

Before shipping, each frame endures hydrostatic load testing and waterproof verification. Delivery arrives on a single truck. Installation by two technicians takes less than two days—no crane, no rebar, no weather delays, and no compromise on factory tolerances.

Interior finishes should do more than just waterproof—they should elevate every sensory detail of the swim. The S-Series Architectural 3D Membrane wraps the structure in a tactile landscape inspired by layered stone, rippled sandbars, and the gentle asymmetry of water-shaped rock.

Advanced German embossing technology presses each nuance into a reinforced polymer composite, balancing grip and glide so precisely that bare feet register security without abrasion.

Beneath the artistry lies Zycore™, a commercial-grade composite that fuses flexible polymer layers with a high-strength polyester matrix, achieving tensile strength near 3,200 psi—four times that of standard concrete. UV stabilizers are co-extruded into the membrane, so color, hygiene, and integrity endure decade after decade.

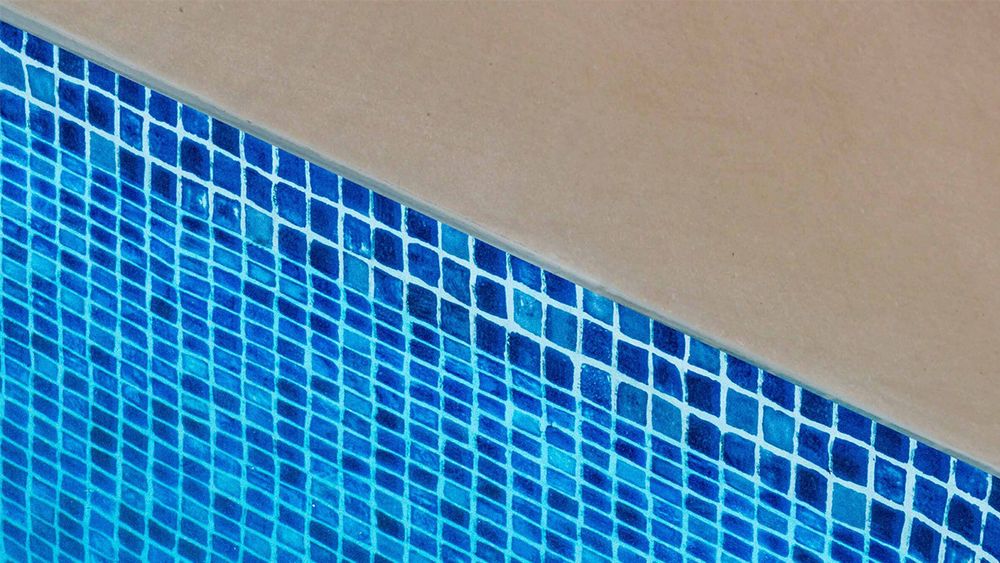

Unlike plaster, it never chalks or etches. Unlike fiberglass, it never crazes. Unlike tile, it offers seamless uniformity with zero grout maintenance.

High-strength steel uses material sparingly by design—requiring 85% less mass than concrete of equal capacity. R-10 insulation cuts heat-loss energy by up to 80%, while optional solar generation balances the remaining load across the year.

Micro-dosing chemistry reduces total chemical use by roughly 40% and eliminates stabilizer byproducts entirely. Every component enters a recycling pathway at the appropriate time.

Owning an S-Series feels less like maintaining equipment and more like overseeing a quiet investment. Daily interaction is limited to glancing at the dashboard or stepping into water that simply feels better—warmer when the air is cool, cooler when the sun blazes.

Chlorine remains too low to sting eyes, yet microbes never gain footing. Service is dictated by data, not a date on the calendar.

Ecopool’s Architectural 3D Membrane transforms pool interiors from mere waterproofing to a sensory experience. Inspired by natural textures like rippled sandbars and layered stone, its embossed surface balances grip and glide—comfortable underfoot and smooth to the touch. Made from a hygienic, non-porous polymer composite called Zycore™, it resists algae, staining, and chemical damage far better than plaster, fiberglass, or tile. With built-in UV protection, it holds its color and integrity for decades while reducing maintenance and sanitizer use. Fully recyclable and available in designer shades, it’s a durable, modern alternative to outdated finishes.

Because every pool bolts together through tube-node interfaces, the S-Series can be relocated without demolition or transitioned from above-ground to inground as circumstances change. At end-of-life—projected beyond 40 years—high-strength steel re-enters the metals stream at high value.

This modularity protects both investment and environment.

Beneath the surface lies Zycore™, a commercial-grade composite engineered in Germany. It fuses flexible polymer layers with a high-strength polyester matrix, achieving tensile strength around 3,200 psi—four times that of traditional concrete renders. UV stabilizers are co-extruded into the membrane, ensuring color and integrity last for decades without fading or damage.

Unlike plaster, it never chalks or cracks. Unlike fiberglass, it won’t craze. And unlike tile, it has no grout to maintain. The smooth, inert surface helps stabilize water chemistry, reducing sanitizer use and saving both time and chemicals. Fully recyclable and incredibly durable, it’s a finish that makes gunite and plaster feel like relics of the past.

The S-Series is a proposition for those who prefer proof to promise: a vessel hand-crafted from high-strength steel that keeps water immaculate, energy neutral, and maintenance discreet.

From purchase order to first swim, the timeline is measured in weeks. From then on, performance is measured in facts, documented and published. The water will not just be ready when you are—it will be right.